MiCo

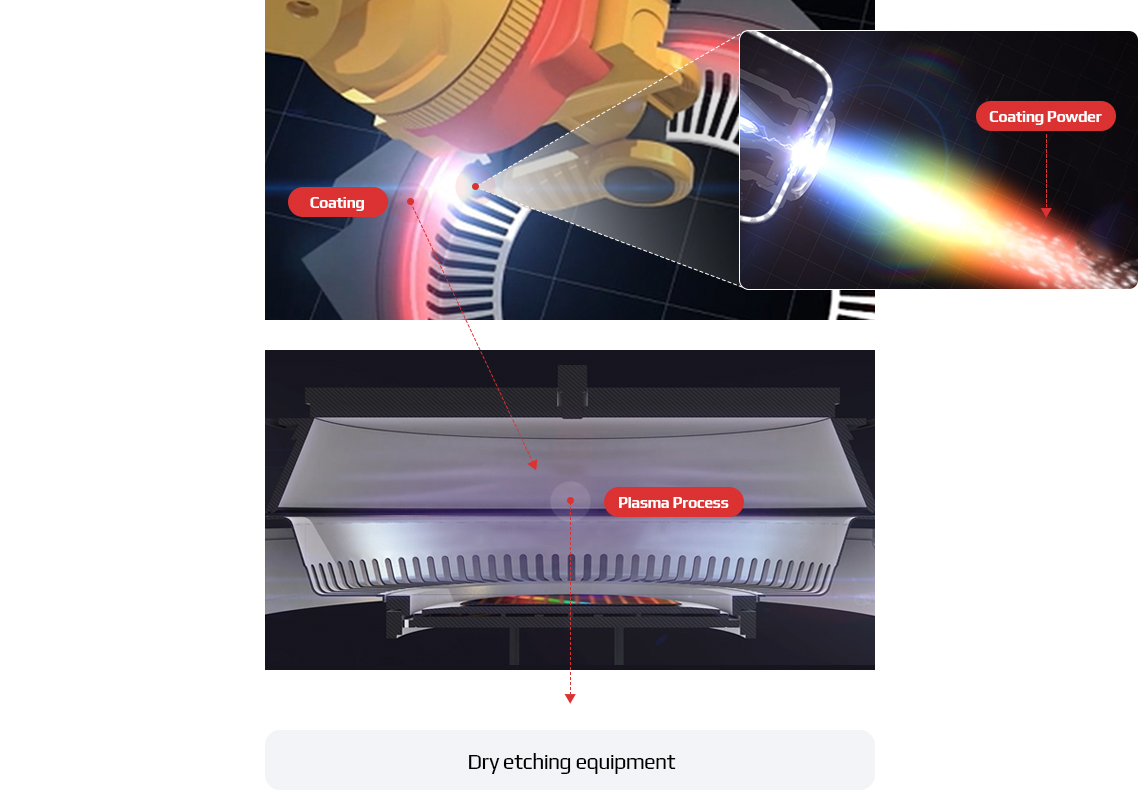

Coating Powder

MiCo’s coating powder is a functional powder manufactured through granulation technology using ceramic raw materials to coat parts with a high-quality layer.

In addition to Y2O3, which is widely used in semiconductor equipment components, MiCo is dedicated to the development of advanced materials for next-generation semiconductor manufacturing processes. To meet customer demands, MiCo applies the innovative coating powders that provide enhanced plasma resistance, extended lifespan, and improved process characteristics.

Characteristics of Coating Powder

Characteristics & Advantages of Coating Powder

Y2O3

- · Excellent plasma resistance

- · Control of particle generation in process

- · Available to control the characteristics of primary particle & granule

(granule size, density, etc)

Yttrium Aluminum Oxide

- · Excellent plasma resistance

- · Crystal-phase controllable (YAG, YAP, YAM)

- · Control of particle generation in process

Fluorides (YF3, YOF)

- · Minimizing reaction with plasma gas

- · Reduction of seasoning time

- · O/F content controllable

Special coating materials

- · Implementation of high density coating

- · High flowability of fine Powder (≤ 20 ㎛)

- · Various coating materials applicable

Slurry for SPS coating

- · Implementation of ultra-high density coating

- · Suppress of particle generation by maximizing plasma resistance

- · Various coating materials applicable

Source for PVD coating

- · Implementation of ultra-high density & ultra-low roughness coating

- · Suppress of particle generation by maximizing plasma resistance

- · Available to control coating source & density

Application

Coating materials for semiconductor etching equipment

Dry etching process