We have developed and manufactured Electrostatic Chuck(ESC) which is a core part of dry etcher equipments for display, and supplied to major domestic and foreign customers.

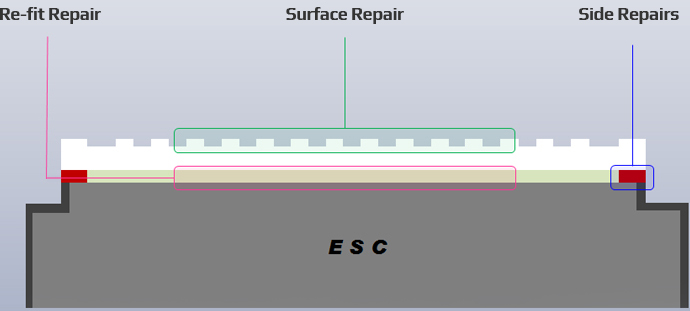

The Ceramic ESC for display has Upper Electrode and Lower Electrode, which holds and fix the panle through electrostatic forces in the Dry Etcher equipment.

Our company has secured competitiveness through continuous technology development, process improvement, and extepansion of mass-production lines, including success in mass-production of 10.5th generation products for the first time in Korea in 2016. With all our sucesses and technologies, we provides a variety of services such as brand new products, front side repair, and full repair.